Interesting question from a visitor recently, how much does air compress at 100 PSI?

What Is PSI?

PSI is a unit of pressure or stress and is expressed in pounds of force per square inch of area. That is, Pounds per Square Inch and therefore PSI stands for Pounds per Square Inch (symbol: lbf/in² abbreviation: psi).

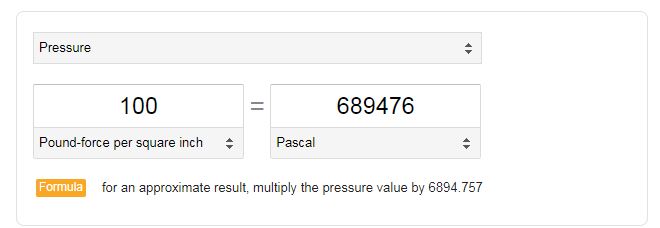

In real terms, 1 PSI = 6894 Pascals = 0.070 atmospheres = 51.715 torr. In SI units, 1 psi is approximately equal to 6895 N/m².

So, in practical terms, PSI is the pressure or stress resulting from a force of one pound applied to an area of one square inch.

What About Ambient Air and 100 PSI?

As you sit there reading this, you are bathed in ambient air, standard air, which is about 14.7 PSI at sea level and at a specific temperature.

The 14.7 is generally considered as one atmosphere, and you don’t notice it, given that you’ve been living and breathing air at that pressure since you were born.

The 14.7 PSI for one atmosphere will change slightly as the air temperature changes, depending on how high you are compared to sea level, and the relative humidity of the air. But for our purposes, and for most compressed air applications, 14.7 will suffice.

The air gage on your compressor shows zero, when the air pressure is really 14.7. It’s been adjusted to read that way. That’s known as PSI gage, as opposed to PSI actual.

Back to our question. If you end up with 100 PSI how much compression has taken place? Divide 100 by 14.7 and you get 6.8. That’s how many atmospheres have been squeezed into one cubic foot to achieve 100 PSI.

Multiples

In some cases, you may want to express PSI in multiples for larger or smaller measurements. These are scaled units derived from PSI. Here are some PSI multiples:

KSI: KSI or kilopound per square inch (ksi) is equivalent to a thousand psi (1000 lbf/in2). This multiple is mostly used in material science whee you are talking about alot of pressure!

The conversion in SI units is 1 ksi = 6.895 MPa, or 1 MPa = 0.145 ksi.

Mpsi: Mpsi or megapound per square inch is another PSI multiple and is equal to a million PSI. Now, this multipole is used for tremendous pressure measurements. This measurement is often used in mechanics and material science.

The conversion in SI units is 1 Mpsi = 6.895 GPa, or 1 GPa = 0.145 Mpsi.

I like that you explained that in some cases you want to express psi in multiples. I’ve been trying to wrap my head around air cannons and how they compress air. This article was very helpful to give me a better idea of what goes into air compression.

Hi, don’t kno if you can help me or not but here goes. Two days ago at work, a 1 1/2″ air line busted where plastic met metal and 180 lbs of pressure blasted into my side and right hand and forearm at pointblank range. Needless to say, it burnt me really bad, along with rust particals/debris flying into my skin. Doc gave me a tetanus shot, burn cream, and antibiotics. My question is, is there any way to tell the speed or pressure (pounds) of force of what hit me?

Hi Bobby. So sorry you got hurt in an accident using compressed air. A 1 1/2″ air line full of 180 PSI air has a lot of potential energy, and when a line lets go at a fitting, the hose tends to fly around very, very quickly. I’m not quite sure how the line burnt you, though? Are you referring to an abrasion as the moving air line hit your arm? Where did the rust particles come from, too?

As to force, well you did say that the line had 180 PSI in it. That means that every square inch of surface area inside the hose has 180 pounds pushing against it, trying to get out. Regarding the force of what hit you, I’m not clear on even what it was that hit your arm?

Regardless, good luck, and heal up fast.

Bill

Hey!

I have a 4500psi 68cu compressed air tank. I was wondering if I used that tank(tank A) to fill another tank(tank B) to 100psi, how many cu in would tank B have to be? Thanks!

-Greg

Hi,

Was just wondering if you are able to tell me in simple terms how you compress air? Im studying teaching and want to be able to have this information so that i can teach the students (unit atm is science :s)

Thanks

Kristie

Hi Kristie. Sure. Just visit my air compressor site, http://www.about-air-compressors.com, and you’ll find tons of info, along with pages on how air is compressed. Any further questions, just use the ASK page there.

Bill

hi, quick question along similar lines. if got an engine that has a compression ratio of 10.9:1, im trying to figure out what psi that works out to be at maximum compression.

thanks in advance

I sure hope that there is a mechanic out there that reads this post. I haven’t a clue! 🙂

B.

10 cubic centimeters is the total cylinder and hemispherical (generally) area in the head. 9 cubic centimeters is the stroke of the piston in the block/bore. As the piston moves up it compresses the mixture into the remaining area 1 in the head, which gives you 10 compressed by 9 into 1. 10.9:1. Naturally aspirated petrol engines use this general capacity as they ignite the fuel air (nitrous) mixture with a spark, diesel engines use the heat of compression which is why they run higher compression ratios. As the diesel air mixture is compressed, it generates heat which causes combustion. It is good to play with all these variables, but you would want to have deep pockets. For all engines you can machine the head down to increase capacity, or you can run a turbo/supercharger/nitrous and an inter cooler to get a denser mixture for a bigger bang. Where are my pistons? Why did the heads just come through my hood? Why is my sump on the ground and my car on fire? You reply with the answer after experimentation.

Sorry that should have been to decrease capacity by machining the head, my editor is on holidays.

Bill,

For a science project, I am making a compressed water-air cannon.

I am (safely) pressurizing a water and air mixture to about 100 psi in a pipe, which I need to rapidly release with some kind of valve in order to launch anything.

What kind of reusable valve can I use to rapidly release pressure in a 1/2 inch diameter pipe?

If the pipe is plastic, don’t do it!

In order for your cannon to work, you need to be able to open up the full bore of the reservoir so that the air can flow out (almost at the speed of sound) without hindrance. What you need then is a 2/2 NC valve of the same bore size of your pipe. You may not be able to find one.

What you may need to do is build a valve that can be operated with a smaller compressed air valve, so that you use the mechanical advantage of compressed air to do the work.

Good luck.

Bill

Hi Bill,

I am currently making a water rocket project. I need to compress 100 or 110 psi to a coke bottle. The problem is that every time I go near the 100 psi mark, the cap fails and leaks air. I used epoxy clay to reinforce it but the same probblem happens. What can you suggest to use as a sealant that can withstand 100 or 120 psi?

Thanks for any help that you can give.

Paolo

__________________

Paolo: I’m not quite sure what a water rocket is, but anytime you over-pressurize any vessel, you risk a catastrophe of sorts. If you are putting 100 PSI into it, make sure it’s rated for that pressure, and I doubt a coke bottle is, so don’t do it!

Tell me what the apparatus looks like and I’ll see if I can give you some ideas as to what will work.

Cheers,

Bill

Try using something such as pn12 pressurized pvc pipe. I’m also pressurizing air for use on a Uni robot, and we’re gonna use that pipe. Research it a bit and see if it will suit what you want it to do

Josh, I certainly don’t recommend the use of any PVC or plastic pipe for compressed air, unless the manufacturer expressly says that their product is suitable. While at room temperature a plastic pipe might appear to have sufficient burst strength for industrial air, get a little heat in the room, and watch the burst strength disappear.

Hello Bill,

I am looking for advice and wonder if you can help me.

I have a ballast tank in a model submarine, which holds 1 litre / 1 kg of water, which i believe is equal to 61 cu inch of volume.

Lets say 60cu in to keep it simple.

I need to be able to pump water into this sealed tank, to compress the air inside, until the tank will fill and hold at least 700ml – 750ml of water. I understand that the tank will never be able to fill to the full litre.

So the question is, what PSI rating of water pump will i need to be able to do this ?

Also, is there a formula that i can apply to this, to find the PSI needed for other size tanks ?

Thanks for any help !

Kind Regards

Rob

Hey Rob….way outside of my ken, that’s for sure.

I don’t have a clue about water pumps.

Sorry,

Bill

So lets say I pumped my water gun up to 100 psi ( I heard you can do this), do you know if that will be very powerful? can 100 psi be damage-inflicting or is it still pretty weak?

______________________________

Godfrey, I’m not sure what a “water gun” is, but it sounds as though you’d be creating a problem.

When you say you pump it up to…I take that to mean there’s a hand pump to allow you to inject air into a tank, and it’s the air in this tank that forces the water out?

It doesn’t sound safe, and I do know that under sufficient pressure, a water jet can cut metal. So be careful!

Cheers,

Bill

so your saying that there are 6.8 cu ft of air in a 1 cu ft tank?

______________________

Nope. What I’m saying is that the cubic feet of air inside a tank will relate to the pressure of the air inside it.

If the pressure inside a 1 cubic foot tank is 14.7, then you will have one cubic foot of free air. If the pressure is 29.4 PSI, then you will have 2 cubic feet of standard (free) air. If the pressure is 147 PSI inside the 1 cubic foot tank, you will have 10 cubic feet of 14.7 PSI (one atmosphere) air crammed into the 1 cubic foot.