[vc_row space_top=”52″][vc_column tdc_css=”eyJhbGwiOnsiYm9yZGVyLWNvbG9yIjoiIzE0MDEwOSIsImRpc3BsYXkiOiIifX0=”]

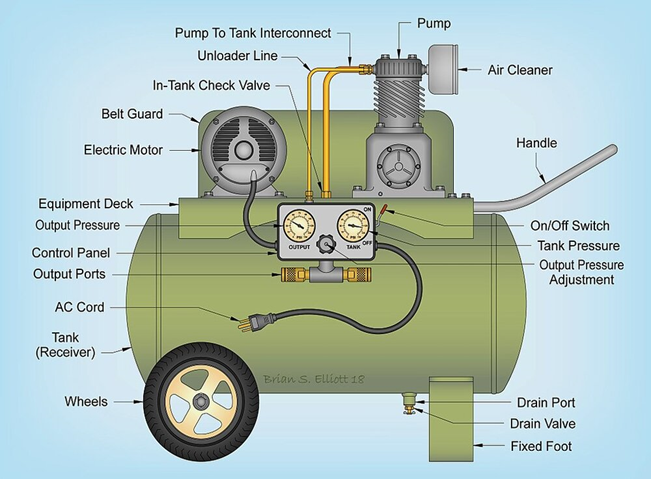

Understanding Air Compressors

This site has guides to help you understand how your air compressor and parts work, air compressor maintenance and DIY advice, and answers to common air compressor problems and questions.

[/vc_column][/vc_row][vc_row][vc_column width=”1/3″]

[/vc_column][vc_column width=”1/3″]

[/vc_column][vc_column width=”1/3″]

[/vc_column][/vc_row][vc_row el_class=”td-ss-row”][vc_column width=”2/3″][/vc_column][vc_column width=”1/3″][/vc_column][/vc_row][vc_row][vc_column width=”1/2″]

[/vc_column][vc_column width=”1/2″]

Air Compressor Manufacturers

[/vc_column][/vc_row][vc_row][vc_column][tdm_block_inline_text description=”T3VyJTIwYnV5aW5nJTIwZ3VpZGVzJTIwaGVscCUyMHlvdSUyMGZpbmQlMjB0aGUlMjByaWdodCUyMGFpciUyMGNvbXByZXNzb3IlMjBmb3IlMjB5b3UuJTIw” display_inline=”yes” f_descr_font_weight=”700″][vc_empty_space][/vc_column][/vc_row][vc_row row_divider_top=””][vc_column]

[/vc_column][/vc_row][vc_row][vc_column][tdm_block_inline_text description=”QWlyJTIwY29tcHJlc3NvcnMlMjBhcmUlMjB1c2VkJTIwZm9yJTIwcG93ZXIlMjB0byUyMGFpciUyMHRvb2xzJTIwZm9yJTIwY29uc3RydWN0aW9uJTJDJTIwZ2FzLWZpbGxpbmclMjBvZiUyMGN5bGluZGVycyUyQyUyMGRpdmVycyVFMiU4MCU5OSUyMHN1cHBseSUyQyUyMHRoZSUyMHBvd2VyJTIwdG8lMjBIVkFDJTIwc3lzdGVtcyUyQyUyMHRoZW4lMjB0byUyMHBuZXVtYXRpYyUyMHRvb2xzJTJDJTIwZmlsbGluZyUyMHZlaGljbGUlMjB0aXJlcyUyMGFuZCUyMHNpbWlsYXIuJTBBJTBBRm9yJTIwaG91c2Vob2xkJTIwdXNhZ2UlMkMlMjB5b3UlMjBjYW4lMjB1c2UlMjBpdCUyMGZvciUyMGJsb3dpbmclMjB1cCUyMGJhbGxvb25zJTIwb3IlMjBhbGwlMjBpbmZsYXRhYmxlJTIwcHJvZHVjdHMlMjB5b3UlMjBtaWdodCUyMGhhdmUlMkMlMjBwdW1waW5nJTIwdGhlJTIwdmVoaWNsZSVFMiU4MCU5OXMlMjBvciUyMGJpY3ljbGUlRTIlODAlOTlzJTIwdGlyZXMlMkMlMjBjbGVhbmluZyUyMGNyZXZpY2VzJTIwd2l0aCUyMGFpciUyMHByZXNzdXJlJTJDJTIwcGFpbnRpbmclMjB3aXRoJTIwYW4lMjBhaXJicnVzaCUyQyUyMGFuZCUyMG1vcmUuJTBBJTBBRm9yJTIwYnVzaW5lc3MlMjB1c2UlMkMlMjB5b3UlMjBjYW4lMjB1c2UlMjBpdCUyMGZvciUzQSUyMHNhbmRpbmclMjBpbiUyMHJlcGFpciUyMHNob3BzJTJDJTIwcGFpbnRpbmclMjBvdmVyJTIwdGhlJTIwdmVoaWNsZXMlMkMlMjB1c2UlMjB0aGVtJTIwZm9yJTIwcG5ldW1hdGljJTIwcm9vZmluZyUyMG5haWwlMjBndW5zJTJDJTIwZm9yJTIwbWFraW5nJTIwZmFrZSUyMHNub3clMjBmb3IlMjBlbnRlcnRhaW5tZW50JTJDJTIwcG93ZXJpbmclMjBhdXRvbW90aXZlJTIwdG9vbHMlMkMlMjBhbmQlMjBzaW1pbGFyLiUwQQ==” display_inline=”yes” f_descr_font_weight=”600″][vc_empty_space]

[vc_empty_space][/vc_column][/vc_row][vc_row][vc_column]

[/vc_column][/vc_row][vc_row][vc_column][tdm_block_inline_text display_inline=”yes” description=”SWYlMjB5b3UlMjBhcmUlMjBoYXZpbmclMjBpc3N1ZXMlMjB3aXRoJTIweW91ciUyMGFpciUyMGNvbXByZXNzb3IlMkMlMjB3ZSUyMGhhdmUlMjBzb21lJTIwYW5zd2VycyUyMGFuZCUyMGFkdmljZSUyMGZvciUyMGNvbW1vbiUyMHByb2JsZW1zLiUyMFRoaXMlMjBpbmNsdWRlcyUyMHdoZW4lMjB5b3VyJTIwYWlyJTIwY29tcHJlc3NvciUyMHdvbid0JTIwc2h1dCUyMG9mZiUyQyUyMG9yJTIwc3RhcnQu” f_descr_font_weight=”600″][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column]

[/vc_column][/vc_row][vc_row][vc_column][tdm_block_inline_text description=”SXQlMjBpcyUyMGltcG9ydGFudCUyMHRvJTIwbWFpbnRhaW4lMjB5b3VyJTIwJTIwYWlyJTIwY29tcHJlc3NvciUyMHRvJTIwa2VlcCUyMGl0JTIwcnVubmluZyUyMGluJTIwb3B0aW11bSUyMGNvbmRpdGlvbiUyQyUyMGZvciUyMHNhZmV0eSUyMGFuZCUyMGElMjBsb25nJTIwbGlmZS4lMjBCZXNpZGVzJTIwZG9pbmclMjBwcmVjYXV0aW9uYXJ5JTIwc3RlcHMlMkMlMjB5b3UlMjB3aWxsJTIwYWxzbyUyMHNhdmUlMjBtb25leSUyMGFuZCUyMHRpbWUlMjB0aGF0JTIwd291bGQlMjB1c3VhbGx5JTIwYmUlMjBuZWVkZWQlMjBmb3IlMjByZXBhaXJzLiUwQSUwQURhaWx5JTIwbWFpbnRlbmFuY2UlM0ElMjBDaGVja2luZyUyMHRoZSUyMGxldmVsJTIwb2YlMjB0aGUlMjBwdW1wJTIwb2lsJTJDJTIwY2hlY2tpbmclMjBmb3IlMjBvaWwlMjBsZWFrcyUyQyUyMGRyYWluaW5nJTIwdGhlJTIwdGFuayUyMHdhdGVyJTJDJTIwY2hlY2tpbmclMjBmb3IlMjB1bnVzdWFsJTIwc291bmRzJTIwb3IlMjBub2lzZXMlMkMlMjBjaGVja2luZyUyMGV2ZXJ5JTIwc2luZ2xlJTIwYWlyJTIwbGVhayUyQyUyMGFuZCUyMGluc3BlY3Rpb24lMjBvZiUyMGJlbHRzLiUwQSUwQVdlZWtseSUyMG1haW50ZW5hbmNlJTNBJTIwQ2hlY2slMjBhbGwlMjBvZiUyMHRoZSUyMGFpciUyMGZpbHRlcnMlMkMlMjBhbmQlMjBpZiUyMG5lZWRlZCUyMGNsZWFuJTIwdGhlbSUyQyUyMG9yJTIwcmVwbGFjZSUyMHRoZW0uJTBBJTBBTW9udGhseSUyMG1haW50ZW5hbmNlJTNBJTIwRG8lMjBhJTIwY2hlY2t1cCUyMG9mJTIwdGhlJTIwc2FmZXR5JTIwcmVsaWVmJTIwdmFsdmUlMkMlMjBjaGVjayUyMGJlbHRzJTIwKGlmJTIwbmVlZGVkKSUyQyUyMHRpZ2h0ZW4lMjB0aGUlMjBib2x0cyUyQyUyMGFuZCUyMGRvJTIwYSUyMGRldGFpbGVkJTIwY2hlY2slMjBvZiUyMHBvc3NpYmxlJTIwbGVha3MlMjBpbiUyMHRoZSUyMGNvbm5lY3Rpb25zLiUwQSUwQVllYXJseSUyMG1haW50ZW5hbmNlJTNBJTIwT25jZSUyMGElMjB5ZWFyJTJDJTIweW91JTIwc2hvdWxkJTIwc2VydmljZSUyMHRoZSUyMGVuZ2luZSUyMG9yJTIwdGhlJTIwcHVtcC4=” display_inline=”yes” f_descr_font_weight=”600″][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column]

[/vc_column][/vc_row][vc_row el_class=”td-ss-row”][vc_column width=”1/3″][/vc_column][vc_column width=”1/3″][/vc_column][vc_column width=”1/3″][/vc_column][/vc_row]

Information how to service and maintain your air compressor and parts.

Information how to service and maintain your air compressor and parts.  Common problems & questions, like “Why want my compressor turn off?”

Common problems & questions, like “Why want my compressor turn off?”